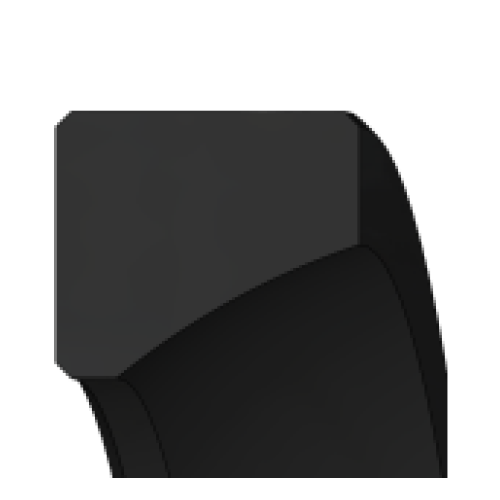

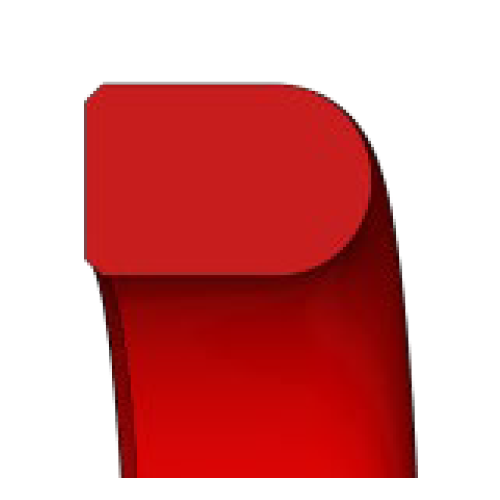

remain the most widely used static seals, offering a simple yet highly effective solution for sealing non-moving interfaces.

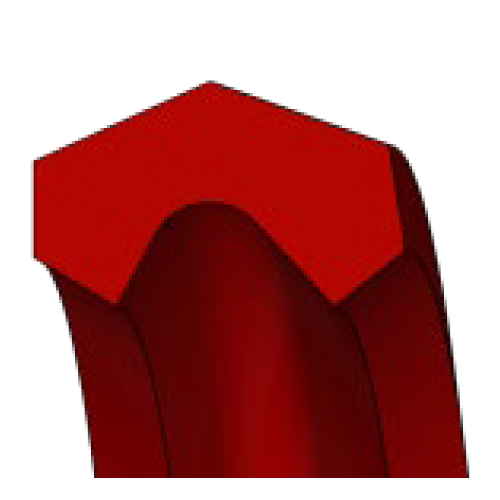

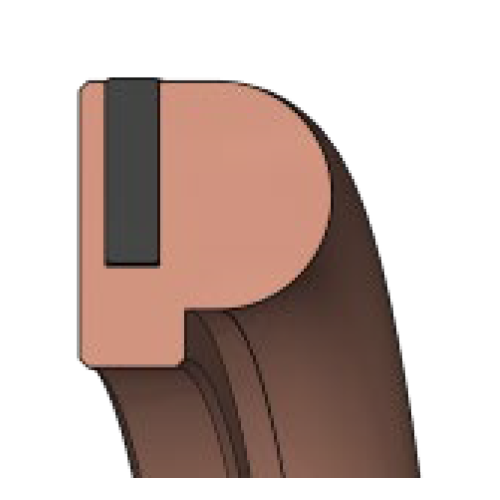

provide flat sealing between two mating surfaces, ideal for flanged connections.

combine a metal washer with an elastomeric element for added strength and sealing precision in high-pressure environments.

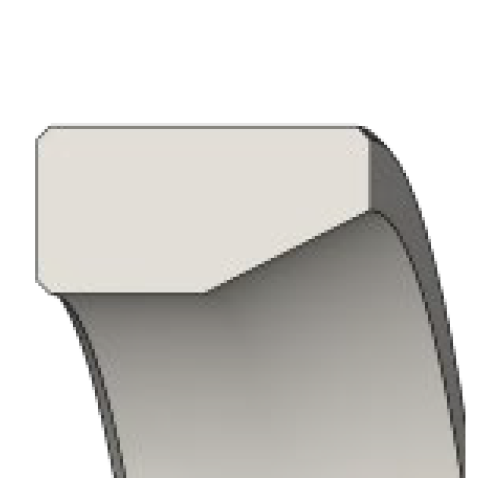

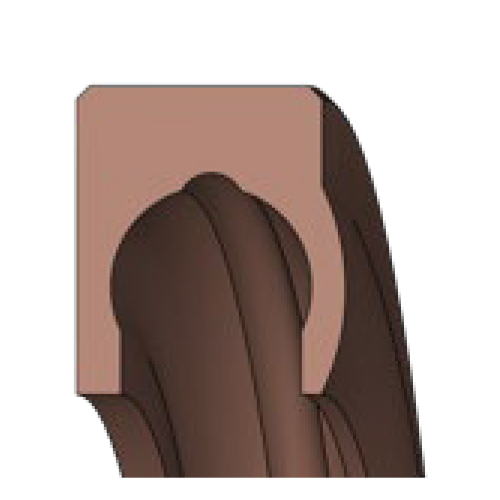

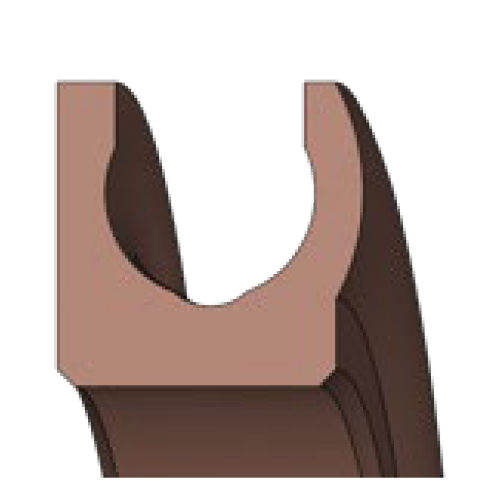

are applied where sealing occurs perpendicular to the mating surfaces.

Good resistance to oils and fuels, cost-effective.

High-temperature resistance and excellent chemical compatibility.

Good temperature resistance and flexibility.

Excellent for water and weather resistance.

Sealing between the cylinder head and body, or between ports and the cylinder.

Sealing between valve body components.

Sealing between pump housing and stationary parts.

Effectively prevent fluid or gas leakage between stationary parts.

Help maintain system pressure by preventing loss of hydraulic fluid or pneumatic air.

Prevent external contaminants from entering the system.

Often simpler in design compared to dynamic seals.

The maximum pressure the seal needs to withstand.

The type of fluid or gas the seal will be in contact with.

The range of temperatures the seal will be exposed to.

The surface finish of the mating components.

Subscribe to our Newsletter & Event right now to be updated