Products

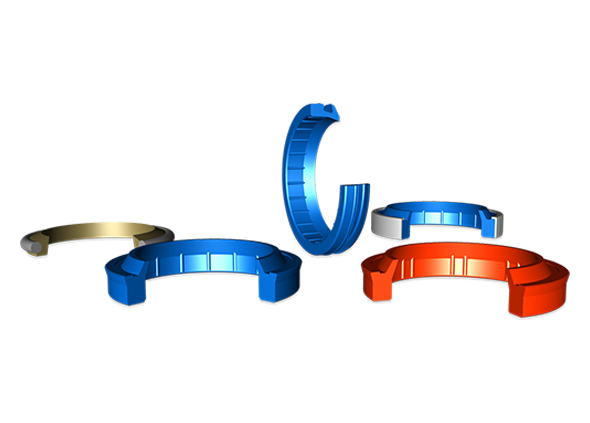

Rod Seals

Piston Seals

Symmetric Seals

Rotary Seals

Wiper Seals

Backup Seals

Double Faced Seals

Wiper Seals for Hydraulic and Pneumatic Applications

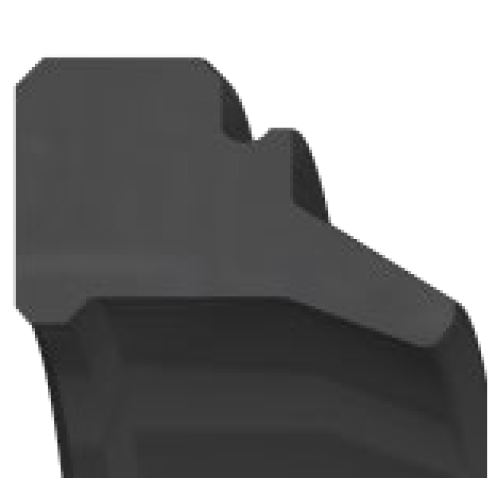

Lip-Type Wipers

feature a flexible lip designed to scrape contaminants off the rod surface efficiently.

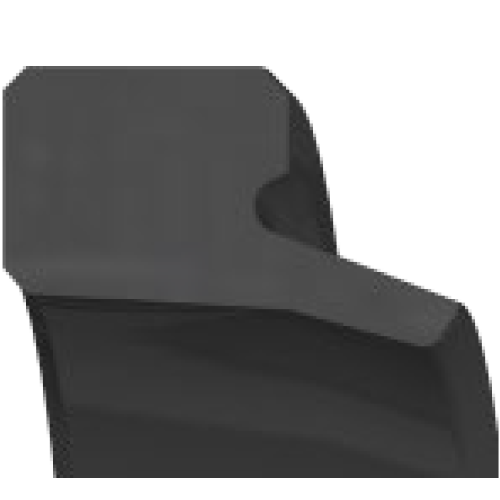

U-Cup Wipers

offer a U-shaped design for powerful wiping action and enhanced protection.

PTFE Wipers

provide low friction along with excellent chemical resistance, ensuring smooth operation in harsh environments.

Understanding the different wiper seal types is crucial for selecting the right solution for your system. Combining hydraulic rod seals with durable wiper seals and guide rings creates a comprehensive sealing solution that extends the lifespan of hydraulic cylinders. Choose from our range of dust-proof wiper seals for industrial machinery and experience improved performance with reliable hydraulic rod and wiper seal combinations for longer lifespan.

Materials

Nitrile Rubber (NBR)

A common and cost-effective choice for general-purpose applications.

Polyurethane (PU)

Excellent abrasion and tear resistance, ideal for demanding applications.

Viton (FKM)

For high-temperature and chemically aggressive environments.

Applications

Hydraulic Cylinders

In construction equipment, agricultural machinery, industrial presses, and mobile hydraulics.

Pneumatic Cylinders

In automation systems, robotics, packaging equipment, and manufacturing processes.

Telescopic Cylinders

Where multiple stages of the cylinder extend and retract.

Key Features and Benefits

Contamination Prevention

Effectively remove contaminants from the rod surface, preventing them from entering the system.

Extended Seal Life

By minimizing contamination, wiper seals help prolong the life of other seals in the system, such as rod seals and piston seals.

Reduced Wear and Tear

Protect internal components from abrasive wear caused by dirt and debris.

Improved System Performance

Contributes to smoother and more reliable operation of hydraulic and pneumatic equipment.

Selecting the Right Wiper Seal

Rod Diameter

The diameter of the piston rod or cylinder rod.

Temperature Range

The range of temperatures the wiper will be exposed to.

Operating Speed

The speed of the rod movement.

Contaminant Type

The type of contaminants the wiper needs to remove.