Products

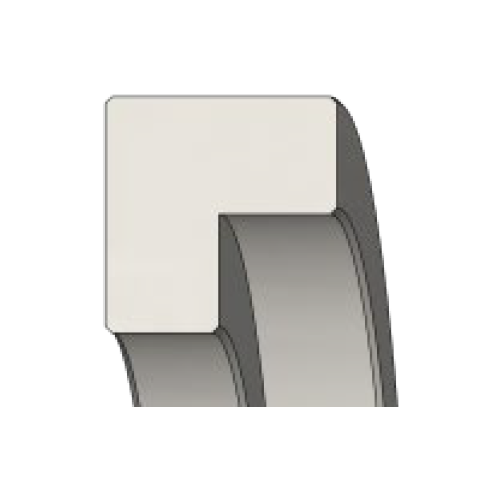

Rod Seals

Piston Seals

Symmetric Seals

Rotary Seals

Wiper Seals

Backup Seals

Double Faced Seals

Guide Rings for Hydraulic and Pneumatic Applications

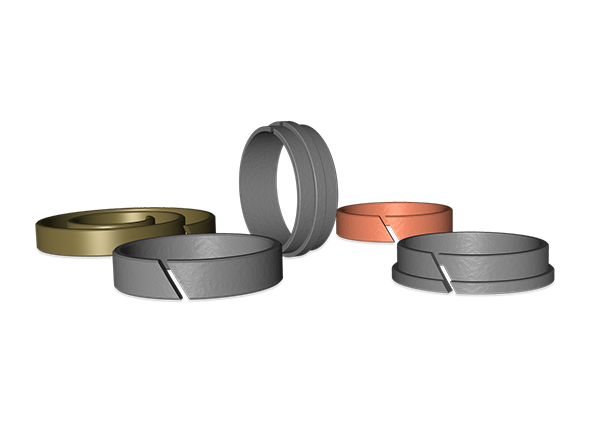

Our range includes:

Cut/Split Rings

Easy to install and ideal for less demanding applications.

Solid/Continuous Rings

Provide superior stability and enhanced load-bearing capacity.

Wrapped Rings

Constructed from strips of material wrapped around the piston or rod for added durability.

Composite Rings

Engineered from combined materials for optimized performance and wear resistance.

Materials

PTFE (Teflon)

Low friction, excellent chemical resistance, and suitable for high-speed applications.

Nylon

Good wear resistance and impact strength.

Acetal

High stiffness and dimensional stability.

Bronze-filled PTFE

Enhanced wear resistance and load-bearing capacity.

Applications

Hydraulic Cylinders

In construction equipment, agricultural machinery, industrial presses, and mobile hydraulics.

Pneumatic Cylinders

In automation systems, robotics, packaging equipment, and manufacturing processes.

Telescopic Cylinders

Where multiple stages of the cylinder extend and retract.

Why Use Guide Rings?

Prevent Wear and Scoring

Guide rings prevent direct contact between the piston/rod and the cylinder bore, minimizing wear and scoring, which can lead to leaks and premature failure.

Extend Cylinder Life

By reducing wear, guide rings significantly extend the service life of the cylinder, reducing maintenance costs and downtime.

Improve System Performance

Guide rings ensure smooth and stable movement of the piston and rod, improving the overall performance and efficiency of the hydraulic or pneumatic system.

Reduce Friction

They minimize friction between moving parts, contributing to smoother operation and energy efficiency.

Selecting the Right Guide Ring

Cylinder Dimensions

The diameter of the piston rod or piston and the cylinder bore.

Temperature Range

The range of temperatures the ring will be exposed to.

Operating Pressure

The maximum pressure the guide ring needs to withstand.

Fluid Compatibility

The type of fluid or gas the ring will be in contact with.