read the article

Which Wiper Seal Type Is Right for Your Application?

A Selection Guide for Industrial Buyers

- By Pareliteseals

- 03/07/2025

- No Comments

- Architecture

Key Points

- Hydraulic wiper seals prevent contaminants like dirt and dust from entering hydraulic cylinders.

- Common wiper seal types include single-action, double-acting wiper seals, PTFE wiper seals, and metal-reinforced wiper seals.

- Material selection—such as polyurethane wiper seals or PTFE—depends on contamination level, operating temperature, and environment.

- Consider system design, space constraints, and rod speed when choosing scraper seals for hydraulic systems.

- Consult trusted manufacturers like Parelite Seals for custom wiper seals tailored to your hydraulic equipment.

What Are Wiper Seals?

Wiper seals, also known as scraper seals, are essential components in hydraulic cylinders, designed to keep contaminants like dirt, moisture, and dust from entering the system. These seals are mounted externally and clean the piston rod as it retracts, protecting internal components such as rod and piston seals. Understanding what are the different types of wiper seals used in hydraulic cylinders is critical to prolonging the service life of your equipment. At Parelite Seals, we manufacture a wide variety of industrial wiper seals, offering customized solutions to suit the most demanding hydraulic applications.

Comprehensive Guide to Selecting Wiper Seals for Hydraulic Applications

Hydraulic systems are widely used across industries—from construction and agriculture to aerospace and industrial manufacturing. These systems face various environmental challenges, and selecting the right hydraulic cylinder wiper seal is crucial to minimizing wear and ensuring reliability.

This selection guide will walk you through:

- Types of wiper seals

- Material choices like PTFE wiper seals and polyurethane wiper seals

- Application-based seal recommendations

- Selection tips based on contamination level, rod speed, and pressure requirements

Types of Wiper Seals

Wiper seals come in various designs, each tailored to specific applications and operating conditions. Below is a comprehensive list of common wiper seal types, categorized by their design and functionality:

1. Single-Action Wiper Seals

- Description: Designed to wipe contaminants off the rod during retraction only.

- Applications: Suitable for general-purpose hydraulic wiper seals in clean or moderately contaminated environments.

2. Double-Acting Wiper Seals

- Description: Provide sealing during both extension and retraction.

- Applications: Ideal for applications requiring enhanced sealing, such as heavy-duty machinery.

3. PTFE-Based Wiper Seals

- Description: These seals incorporate PTFE (Teflon) for low friction and high chemical resistance.

- Applications: Best for applications with high chemical exposure or low-friction requirements.

4. Metal-Reinforced Wiper Seals

- Description: These seals feature metal reinforcements for added durability in harsh environments.

- Applications: Suited for construction, mining, or other high-contamination environments.

5. Specialized Wiper Seals

- Description: These seals are designed for specific conditions or applications.

- Examples:

- Aggressive Wipers: For heavily contaminated environments like construction or agriculture.

- Small Height Wipers: For applications with limited space, such as compact cylinders.

- Heavy-Duty Wipers: For tough conditions with built-up debris, often made from rigid engineering plastics.

- Press-In Design Wipers: Provide a low-friction wiping lip, suitable for both hydraulic and pneumatic systems.

- Applications: Tailored for unique system requirements or space constraints.

6. Lip Geometry Variations

- Description: The shape of the wiper seal’s lip affects its performance:

- Single Lip, Straight Wiper Lip: Most aggressive, ideal for(high contamination environments.

- Single Beveled/Chamfered Wiper Lip: Less aggressive, suitable for moderately contaminated environments.

- Single Rounded Seal Lip: Least aggressive, used in pneumatic applications to maintain an oil or grease film.

- Double/Redundant Wiper Lips: Improves sealing, often paired with long-life rod seals for the driest sealing performance.

- Applications: Chosen based on the level of contamination and sealing requirements.

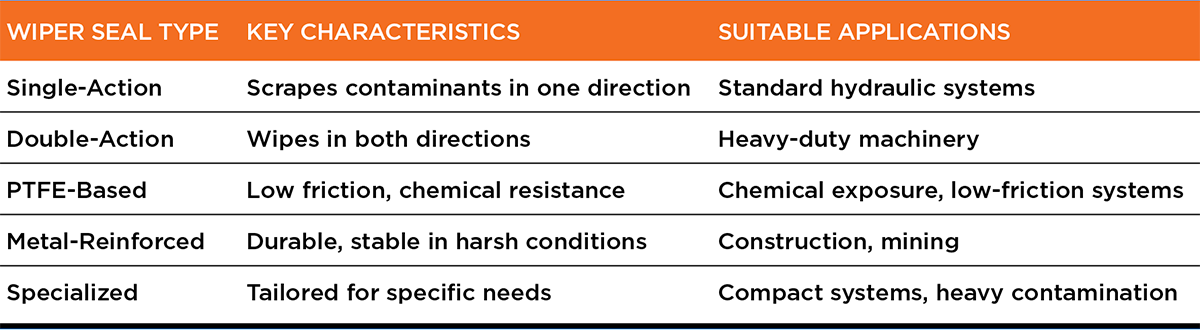

Summary Table of Wiper Seal Types

Materials for Wiper Seals

Material selection plays a vital role in wiper seal performance. At Parelite Seals, we offer a wide range of materials for hydraulic wiper seals:

- Polyurethane (PU): Excellent for abrasive environments. Choose polyurethane wiper seals for their toughness in applications with heavy dirt and debris.

- PTFE: Offers the best chemical and temperature resistance. Ideal for clean environments or aggressive chemical exposure.

- Viton, NBR, and Silicone: Available for specific temperature or chemical resistance needs.

Looking for guidance on material selection? Read our guide to selecting wiper seals based on contamination level and rod speed.

How to Select the Right Wiper Seal for Hydraulic Equipment

Choosing the right wiper seal isn't just about material—it's about understanding your full operating environment. Here's how to approach it:

1. Contamination Level

- High Contamination: Use aggressive wipers with single straight lips or metal-reinforced designs for environments like construction or mining.

- Moderate Contamination: Opt for wipers with beveled or chamfered lips for industrial settings with moderate debris.

- Low Contamination: Wipers with rounded seal lips are sufficient for cleaner environments or pneumatic systems.

2. Operating Environment

- Temperature Range: Select materials that match your operating temperatures. For example, Viton for high temperatures (up to 400°F/200°C) or Silicone for low temperatures (down to -40°F/-40°C).

- Chemical Exposure: Choose PTFE or Viton for systems exposed to aggressive chemicals.

3. System Design

- Rod Speed and Size: Ensure the wiper seal can handle the rod’s surface speed (up to 13 ft/s or 4 m/s for most seals) and diameter.

- Space Constraints: Use small height wipers for compact cylinders with limited space.

4. Sealing Requirements

- Single vs. Double Action: Single-action wipers are sufficient for standard applications, while double-action wipers provide enhanced sealing for heavy-duty systems.

- Pressure Relief: Consider wipers with pressure relief features to prevent pressure traps in high-pressure systems.

5. Durability and Longevity

- Material Hardness: Harder materials like polyurethane offer durability but may increase friction. Softer materials like NBR provide flexibility but may wear faster in harsh conditions.

- Reinforcement: Metal-reinforced wipers are ideal for rugged applications requiring extra stability.

Industry-Specific Applications

Wiper seals are used across various industries, each with unique requirements:

- Construction and Agriculture: Aggressive wipers and polyurethane seals handle heavy dirt and debris

- Automotive: Wiper seals in hydraulic brake systems and suspension systems prevent dust ingress.

- Aerospace: High-performance seals like Viton or PTFE ensure reliability in extreme conditions

- Industrial Machinery: Nitrile rubber wipers offer flexibility for moderate contamination levels.

Why Choose Parelite Seals?

Conclusion

Selecting the right wiper seal is critical for protecting your hydraulic systems from contamination, ensuring optimal performance, and minimizing maintenance costs. By understanding the different types of wiper seals, their materials, and the specific needs of your application, you can make an informed decision that enhances equipment reliability. Always consult with seal manufacturers like Parelite Seals to ensure you choose the best wiper seal for your hydraulic system.

- TAGS

- SHARE